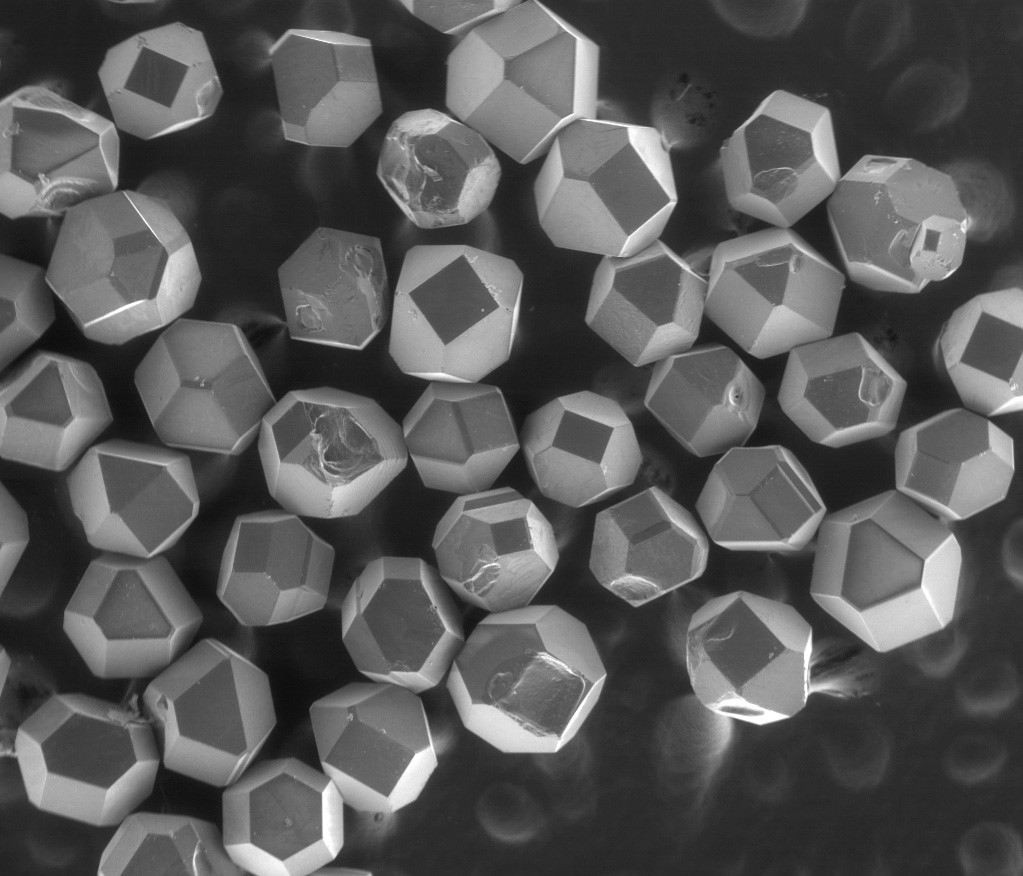

Synthetic diamonds are man-made and have many of the same properties.as diamonds but instead of being valuable for their beauty they are highly desired because of their industrial uses. They are just as hard and offer advantages over traditional diamonds because they can be manufactured to bring out certain properties in the material. Because of their particular qualities man-made diamonds are called a super material and companies like https://www.e6.com manufacture some of the highest grade industrial diamonds that are used todays n many different industries.

We all have heard the phrase “Diamonds are a girl’s best friend”, well in terms of synthetic diamonds the phrase should go, “Synthetic are industry’s best friend”, because of their importance and many critical uses in so many industries.

Here are some of the specific uses and benefits of synthetic diamonds:

- Synthetic diamonds help revolutionise non-invasive surgery and allow operations to be performed in shorter time

- They can be utilised for a whole range of products such as high-quality speakers, tablets and computers They are used in powerful tools that enable faster cutting speeds to improve overall operation

- They deliver extremely long tool life, meaning reliable production and lower machine investment depreciation costs and investment.

Here are some of the industries that use synthetic diamonds and some of their most important uses.

Table of Contents

Healthcare

As operations seek to become less invasive and more precise, synthetic diamond components are at the forefront. Their use can allow operations to be performed in a far shorter time span, which is beneficial to patients, surgeons and hospitals overall. When combined with other new healthcare tech including lasers and fiber optics, they represent the new generation of effective tools for the industry.

Automotive

The use of synthetic diamonds in automobile manufacturing has become standard because of their unique and powerful properties. The automotive industry is such a demanding industry in terms of the manufacture of automotive parts and pieces. Synthetic diamond materials are used in many areas including critical engine and gearbox components, wheel assembly, window manufacture and the finish of smooth, sleek body panels. Supermaterials like synthetic diamonds ensure a consistent production process in engine and powertrains in both defined edge and abrasive applications. They also increase cutting and grinding speeds and extend tool lives, while lowering the total operational costs for every automobile manufacturer.

Consumer Goods

You may not know it but synthetic diamonds are utilised in a whole range of products that we use daily. Music speakers are a great example. The speakers that provide you with high quality music could have been created using diamond technology. A CVD diamond can be ‘grown’ into complex shapes offering a perfect combination of hardness and stiffness. In speakers, A CVD diamond tweeter dome delivers supreme sound quality, all without a hint of distortion. Since synthetic diamonds can cut or drill through almost anything they can deliver a precision finish to your furniture, and can be used to create electrical household items such as tablets and computers. Synthetic diamonds enable high precision production at increased speeds.

Construction

Residential and commercial structures today must be built from hard, resistant material that can withstand water, strong winds, heat and anything else the weather throws at them. The challenge is how to cu these materials and this is where synthetic diamonds shine. These supermaterials are ideal for drilling, cutting and polishing these hard materials making them ideal for the construction industry.

Additionally synthetic diamonds play key roles in aerospace, optics and many other industries. #UltimateSupermaterial.